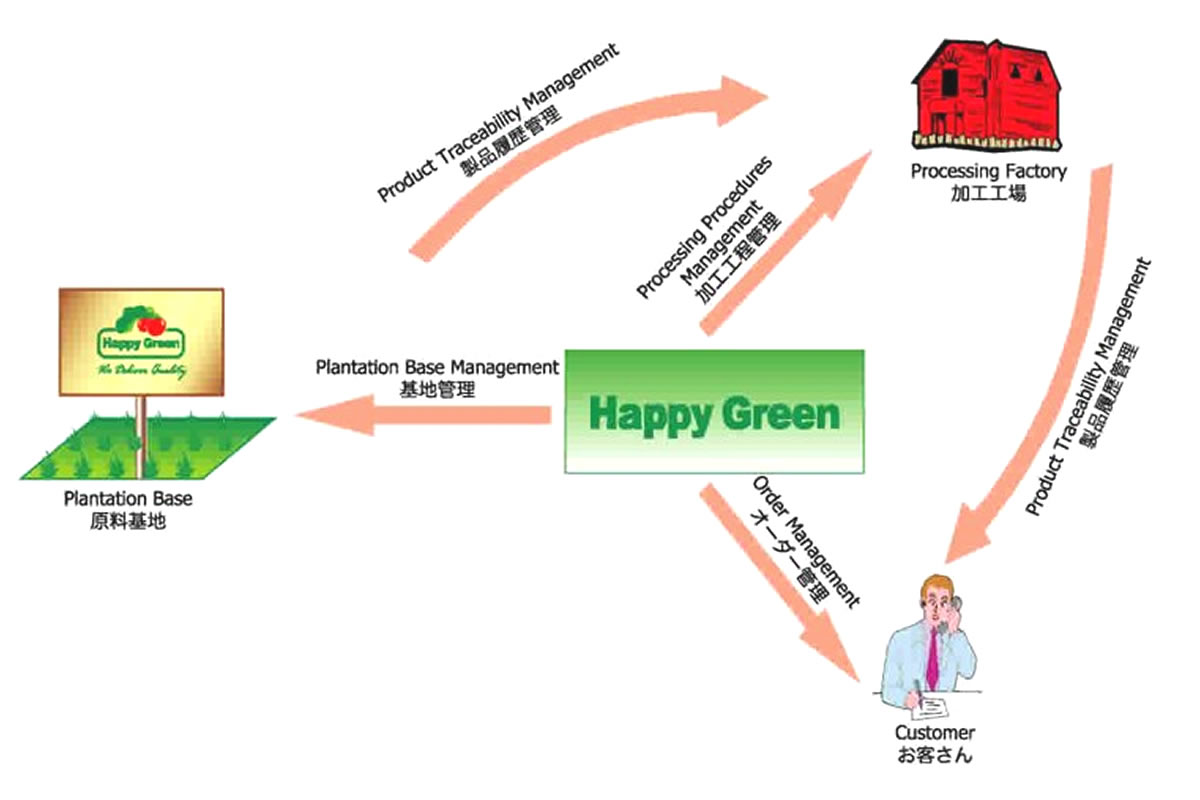

Production Procedures Management

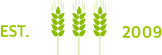

All the factories we are working with are required to have a strict hygiene and foreign material control system.

All our factories have HACCP and they are authority recognized. Some of them have passed third party audits such as AIB, BRC.

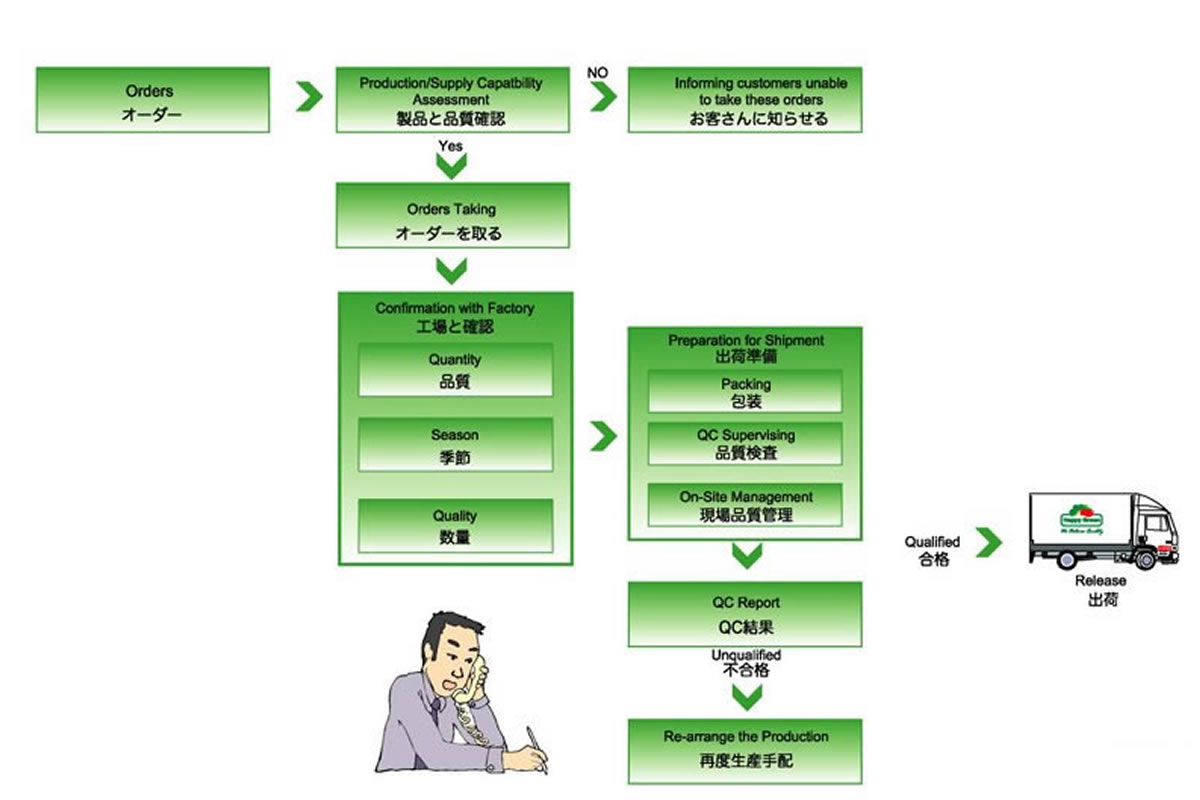

Product Traceability

For food products, we understand that product traceability is more and more an important issue. HappyGreen has developed a system so that each in-coming raw material is coded. This code will be carried on through the production, and shown on the lot No. of the finished product.

In another words, every carton can be traced back to its field/pond where the raw material comes from.

Quality Control System

As being in the food business, we understand no less than others the importance of food safety. At the moment of establishment, we set our company’s logo as “we deliver quality”, which gives us no leeway as far as quality is concerned.

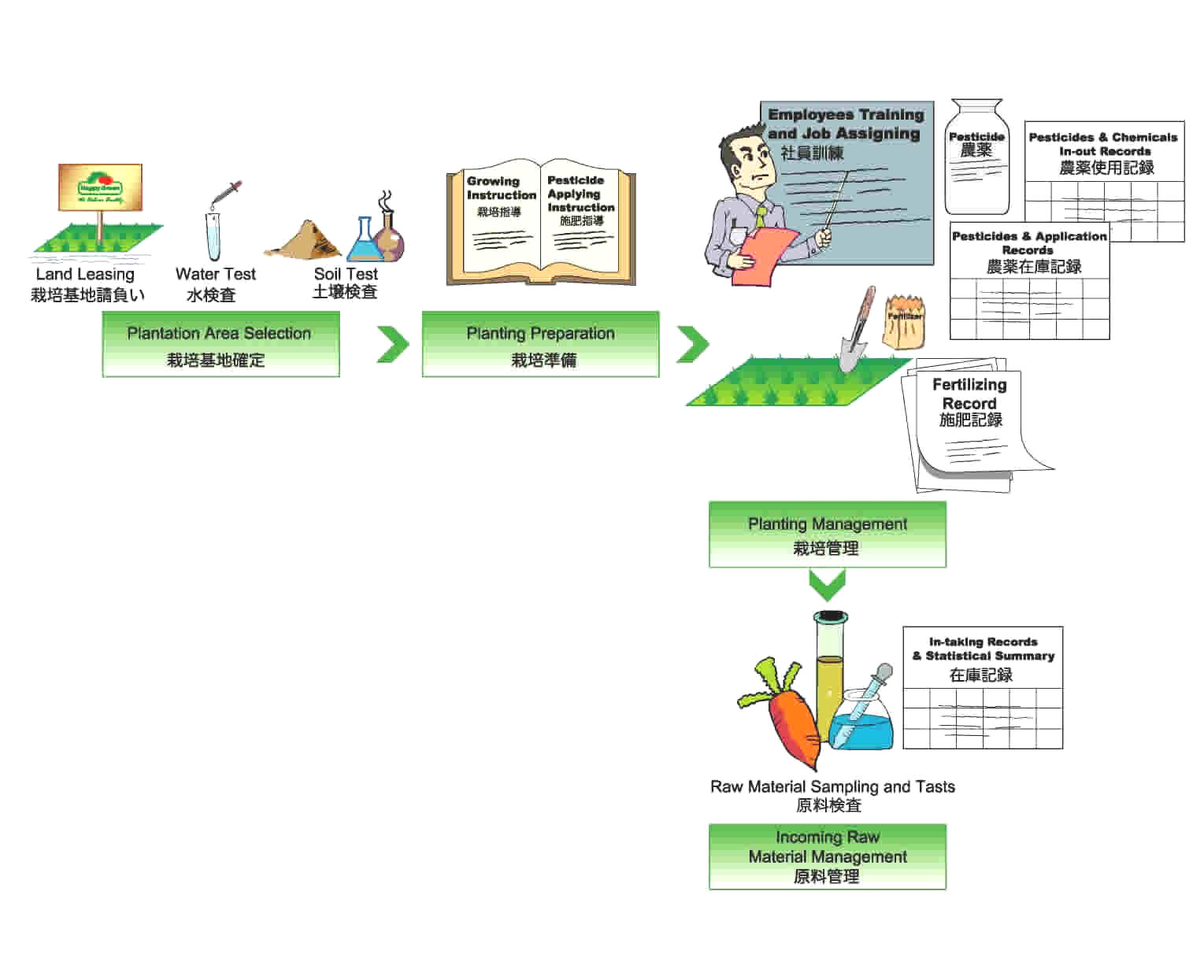

For vegetables and fruits, all our factories have developed their own plantation bases. The pesticide application is strictly controlled so as to ensure the residue is within specification.

For seafood products, we only work with those factories that have a full traceability system and HACCP, to ensure the safety of our products. Each shipment will be sampled and tested prior to release.

In Happy Green, 1/3 of our people are working in QC department. They are visiting one factory after another, to ensure that all the mass production are supervised, each shipment is checked.

Plantation Bases Management

For vegetable products, we understand very well that pesticide residue is of vital importance to human health. All of our factories have developed their own plantation bases, thus to ensure the pesticide are properly applied.